|

irc_ros_hardware package from irc_ros repoirc_ros_bringup irc_ros_controllers irc_ros_dashboard irc_ros_description irc_ros_examples irc_ros_hardware irc_ros_moveit_config irc_ros_msgs irc_ros_navigation2 |

Package Summary

| Tags | No category tags. |

| Version | 0.1.0 |

| License | Apache-2.0 |

| Build type | AMENT_CMAKE |

| Use | RECOMMENDED |

Repository Summary

| Description | ROS2 packages for the igus Robot Control |

| Checkout URI | https://github.com/commonplacerobotics/irc_ros.git |

| VCS Type | git |

| VCS Version | humble |

| Last Updated | 2025-05-21 |

| Dev Status | UNMAINTAINED |

| CI status | No Continuous Integration |

| Released | UNRELEASED |

| Tags | robotics ros ros2 |

| Contributing |

Help Wanted (0)

Good First Issues (0) Pull Requests to Review (0) |

Package Description

Additional Links

Maintainers

- Felix Reuter

Authors

- Björn Schenke

- Felix Reuter

iRC ROS Hardware interface

This package contains the drivers for interfacing with different robots. This can be done both over the CPRCANv2 protocol and the CRI protocol. The CPRCANv2 protocol is more perfomant and provides more functionality. The drawback is requiring more direct hardware access. If an EmbeddedControl unit or a igus Rebel with a base is used, the Raspberry Pi inside could be used. This could interfere with TinyCtrl and stop the robot from working with CRI unless you swap out or partition the SD Card and install a seperate sytem just for the ROS setup on it. While ROS2 and all used nodes should work on the Pi, it was not tested and the performance might be subpar, depending on your application. If you require more performance you can leave only parts of the nodes running on the Pi and e.g. start the visualisation + Nav2 nodes on a seperate device in the same network. Alternatively you could swap out the entire base and connect directly to the CAN bus cable coming out of the first robot axis. In that case you will have to take caution to provide an adequate power supply to the second cable coming out of the robot. In case you have a “ReBeL Open Source” version you are not provided with a base unit by default and need to follow this way.

While the CAN interface has few problems you still must be very careful when operating a robot!

The alternative to CAN is called CRI. Instead of directly interfacing with the bus itself, an intermediary device takes over the bus side and provides functionality such as path planning over the Network. The current CRI hardware interface only works reliable with velocity commands, as TinyCtrl can’t handle streaming joint goals. This will either be resolved by a custom ROS2 controller or an update for TinyCtrl. The CRI interface offers the advantage of working directly with existing robots otherwise controlled by iRC/CPRog.

Do not use the CRI interface for any serious work. It is not yet ready for anything besides testing, if even that.

Usage

The package is intended to be used inside the ROS2_Control ecosystem. The hardware interfaces provide state and command interfaces, which are connected to Controllers. For the movement commands the standard ROS2_Control Controllers are used. For other functionality, DIO and Module states, custom controllers are provided by the irc_ros_controllers package.

CRI

The CRI implementation is based on the TruPhysics ROS package for the igus ReBel. The protocol version should be V17 2022-08-02, although only a small subset of functions is implemented.

The CRI protocol requires a controller computer running a compatible version of TinyCtrl. It should be reachable under 192.168.3.11, otherwise the IP needs to configured accordingly.

CPRCANv2

This aims to implement a subset of the CPRCANv2 protocol. The protocol reference v1.5 released on 2022-07-18 was used, but not all functionality was deemed necessary. The EEPROM commands are not implemented here. Furthermore some undocumented functionality is implemented, notably a movement_ready bit available in more recent rebel axes firmwares.

The can hardware interface works on a per module base. They are collected in the main irc_ros_can class for combined hardware interfaces, but otherwise work independatly from each other. Each module is configured via the .ros2_control.xacro files with their can_id and module type.

Control works both over position and velocity values, in theory also torque control is available but untested. The proper motion information is received by the position state, the velocity state is a simply, noisy calculation between two position states, only used for mobile platform velocity control.

Module info and control is done via the dashboard found in the irc_ros_dashboard package. For debugging the CAN communication candump, cansend and ip link show can0 commands provide a good start.

Hardware Interfaces

Joint states

- hardware_interface::HW_IF_POSITION

- hardware_interface::HW_IF_VELOCITY (Note: very noisy)

DIO states

- (dio_name)_(number)

Module states, found on all devices

- “can_id”

- “temperature_board”

- “temperature_motor”

- “hardware_ident”

- “version_major”

- “version_minor”

- “error_state”

- “motor_state”

- “reset_state”

- “supply_voltage”

Joint commands

- hardware_interface::HW_IF_POSITION

- hardware_interface::HW_IF_VELOCITY

- hardware_interface::HW_IF_EFFORT (Note: untested)

DIO commands

- (dio_name)_(number)

Module commands

- “dashboard_command”

Movement commands

The CPRCAN V2 startup sequence combined with the desire to easily switch between position, velocity and torque control is integrated with an internal state that depends on the claimed interfaces. Only one of the interfaces may be used at the same time.

State machine

These are the current plans and/or statii of the different state machines. Once these are tested with all different hardware combinations these diagrams should be redone in a nicer design.

Motor State

stateDiagram-v2

[*] --> disabled

disabled --> enabling : enable_motor()

enabling --> disabled : timeout

enabling --> enabled : ACK

enabled --> disabled : error state received

enabled --> disabling : disable_motor()

disabling --> disabled : ACK

disabling --> enabled : timeout

The enable_motor() function is called once for a movement startup or via the dashboard interface. Currently disabling is only done manually via the dashboard. It might be an option to disable the motor after a certain delay of no movement commands, if the startup sequence is fast and stable enough.

ReadyToMove

Another state that needs to be checked for the readiness to move is the ready to move bit. On rebel axis modules this indicates for position commands if the set_pos variable can be modified from set_pos=current_pos. It is only set shortly after a successful motor enable and is unset once an error/motor disable occurs.

stateDiagram-v2

[*] --> not_implemented : Din rail module or old firmware

[*] --> not_ready : Rebel axis module with recent firmware

not_ready --> ready : Ready bit received

ready --> not_ready : No ready bit received

ResetState

Used to track the state of error reset commands and error state.

stateDiagram-v2

[*] --> not_reset

not_reset --> resetting : reset_error()

resetting --> reset : No Errors remaining

resetting --> not_reset : timeout

reset --> not_reset : Error received

Note that the reset state is reached via a no error-bits set status message, as otherwise an unhandled status message send beforehand may set the state back to not_reset immediately.

SetToZeroState, ReferenceState, RotorAlignmentState

Used to keep track of the state of the corrosponding commands. Only the referenceState should normally change, as the robot should be in the correct alignment state after startup and the position should always be read out/referenced instead of simply setting it to 0.

Referencing

Older robots without absolute encoders like the Robolink DP 5 need to reference their joint positions on startup. This requires the joints to move to a specific position. This has to be done in a specific order to avoid collisions, which is done during the on_activate method. If the robot was already referenced before this may be read in the standard response.

stateDiagram-v2

[*] --> not_required : e.g. igus ReBeL

[*] --> unreferenced : e.g. Robolink DP 5

unreferenced --> referencing_step1 : referencing() call during on_activate()

referencing_step1 --> referencing_step2 : referencing() call caused by response_1

referencing_step2 --> referenced : response_2

[*] --> unreferenced : response_error

[*] --> referenced : reference bit set in standard response

Timing

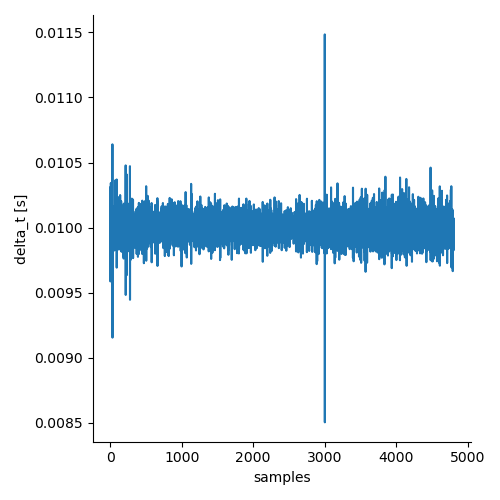

Checking the approximate timing with candump can0,010:FFF -td (010 is for the module 0x10, so the first motor module) shows a relatively stable frequency around the set rate of 100Hz. Plotting the data from the highest can id (in the images case 0x40) shows some jitter, if this causes trouble switching to a real time kernel might help. The example can dump and plotting script can be found in doc/. For further debugging comparing the jitter peaks with the sending of position messages might be of interest, for which the data is already available in the python plot script.

Links

Hardware communication

ROS2_Control Hardware Interface info:

- https://control.ros.org/galactic/doc/getting_started/getting_started.html#hardware-components

- https://control.ros.org/galactic/doc/ros2_control/hardware_interface/doc/hardware_components_userdoc.html

- https://control.ros.org/master/doc/ros2_control/hardware_interface/doc/writing_new_hardware_interface.html

- Proposal for a modular ros-control architecture

Similar ROS2 robot implementations and demos using ros2_control:

- https://github.com/ros-controls/ros2_control_demos

- https://github.com/frankaemika/franka_ros2/tree/develop/franka_hardware

- https://github.com/UniversalRobots/Universal_Robots_ROS2_Driver

- Complete list

Wiki Tutorials

Package Dependencies

System Dependencies

Dependant Packages

| Name | Deps |

|---|---|

| irc_ros_bringup | |

| irc_ros_controllers |